Contact Us For Custom Parts. Eriks O Ring Groove Design.

Eriks Technical Manual O Ring Gland Design Information

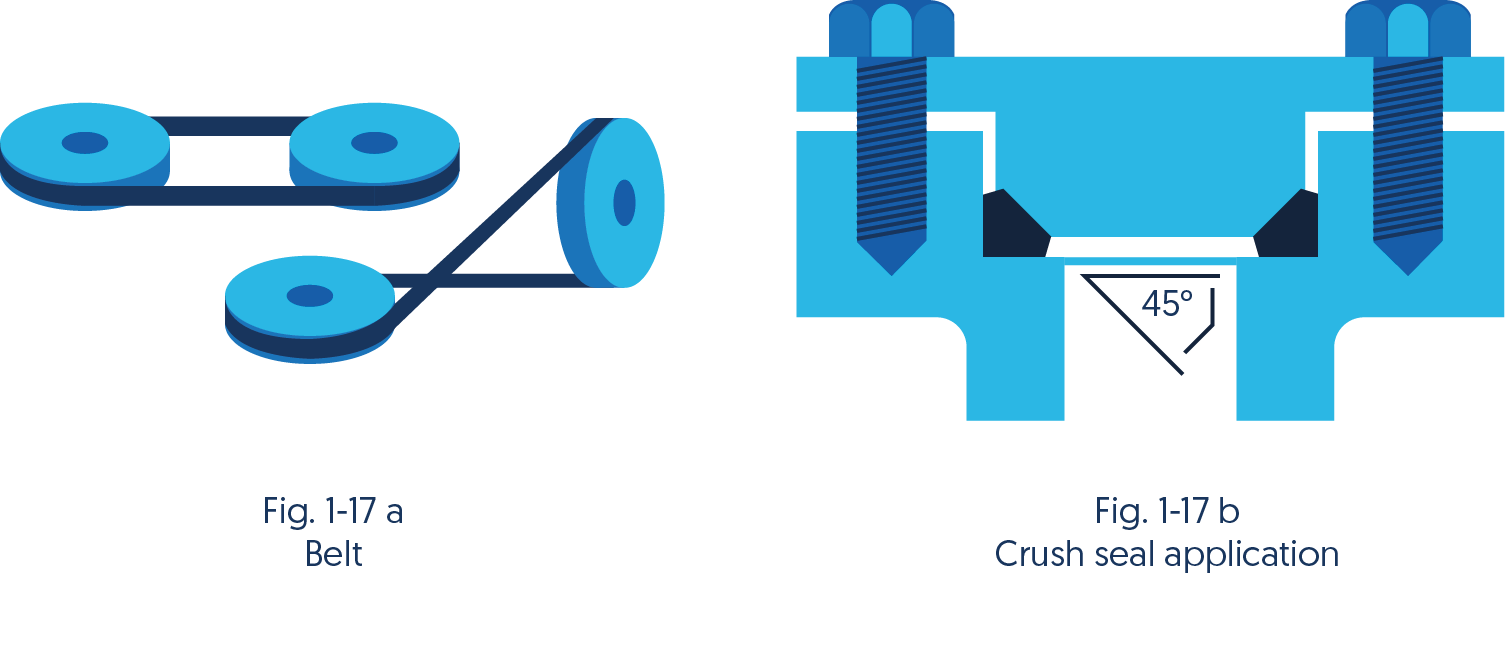

The following information is a guide for oring groove dimensions for both static and reciprocating.

. O-ring dimensions for the use in a specific groove. The groove design allows the O-ring to be retained in the face seal during assembly and maintenance. A lid which opens regularly.

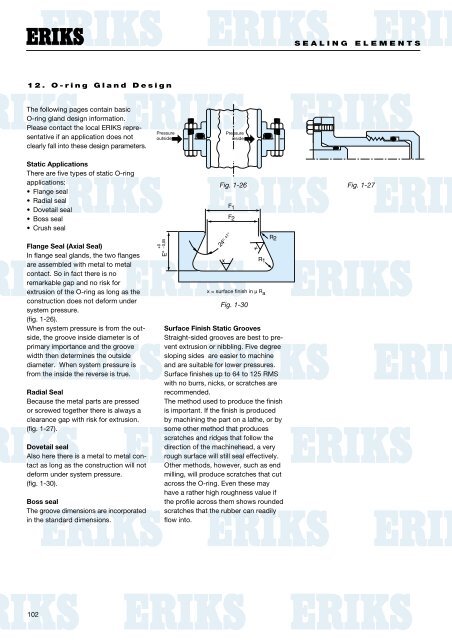

O-Ring Groove Design Overview. The initial sealing is achieved by the diametrical squeeze in a right angled groove. The ERIKS O-ring design calculator features the calculation of.

Female or Tube - the O-ring groove is located in the housing or cylinder and a tube is installed through the O-ring lD. Numerous factors go into the appropriate design of a glandgroove including but not limited to static or dynamic. The groove must be designed to accommodate not just the oring size but also its intended usage.

The O-ring to roll slightly in its groove under certain conditions of motion but the rolling action is not necessary for normal opera-tion of the seal. The shape of the groove is unimportant as long as it results in proper squeeze of the O-ring. As important as the oring seal itself is the groove that the oring seats into.

Groove dimensions for the use of a specific O-Ring. Ring is nearly the same as the O-ring sealing. Wwweriksinfo Technical Handbook O-rings In designing an O-ring seal it is important to determine the O-ring compound early as the compound selected may have an influence on the gland design.

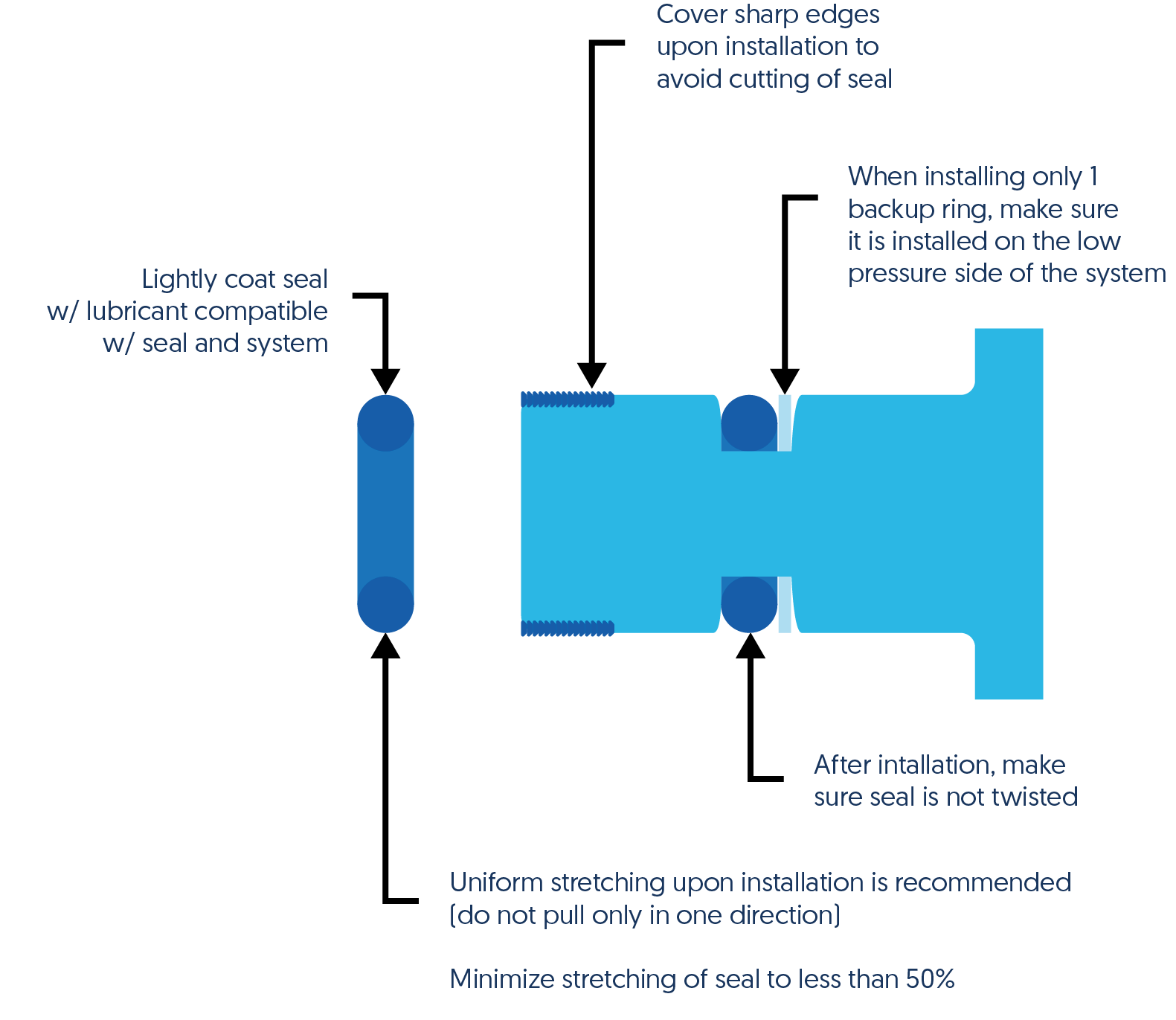

The ERIKS O-ring design calculator features the calculation of. To accommodate the additional back-up rings the O-ring groove width L needs to be increased to L1 for one back-up ring or L2 for two back-up rings. The groove width dimensions are listed in.

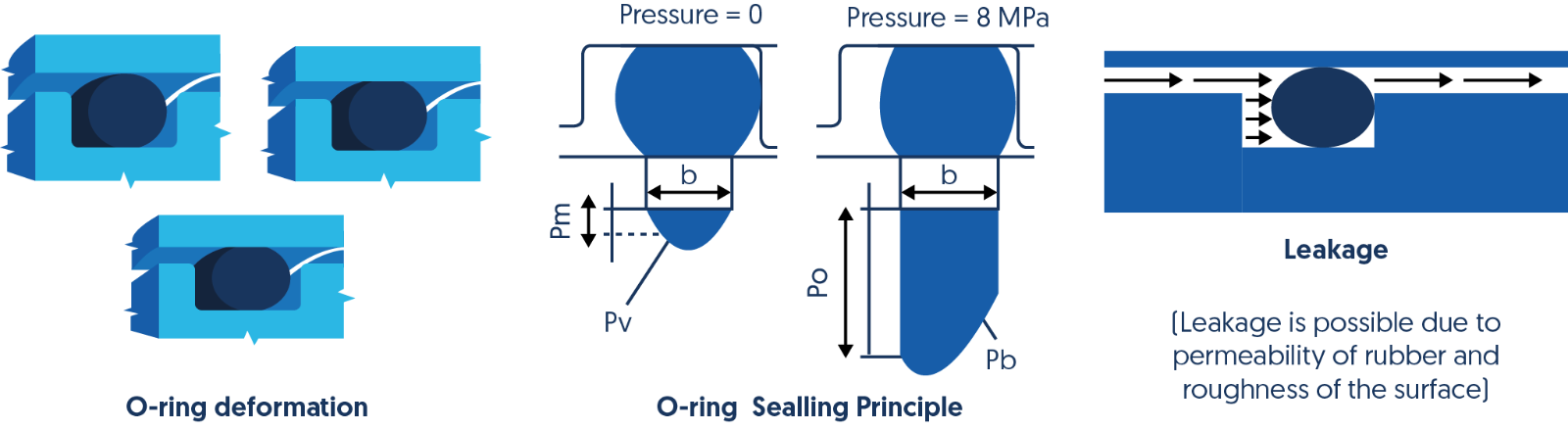

Global O-Ring and Seal has developed o-ring groove design and gland dimension guidelines. The O-ring is also axially squeezed in a dovetail groove. Ad FDA USP 3A Compliant BSETSE Free Viton-EPDM-Silicone-PTFE- Sanifluor-Tyfluor.

For additional information about O-ring and back-up ring materials refer to Materials and about extrusion refer to Gap extrusion. Find materials suitable for use in your media. Be it dynamic or static operation radial or axial loading vacuum or high pressure.

Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. Male or Plug Seal design is based on the following factors refer to fig. This groove design is rela-tively uncommon as it is expensive to machine and should not be used unless absolutely required.

The groove design allows the. Ad 100 Produced In-House Giving You Higher Quality Shorter Lead Times Lower Final Costs. Samples Available for Evaluation.

Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder fig. The dovetail groove construction is only recommended for O-rings with bigger cross sections 139 inch 353 mm and bigger. The calculator takes all relevant parameters into account like.

In order to seal properly the o-ring has to deform in the application by being compressed and stretched in any number of ways. For the Quad-RingsX-Rings not listed the groove dimensions are. Chemical volume swell cross section diameter mm ISO 3601.

O-ring 18585 Tradename Teflex 657 Material CR 233 EPDM. Select a standard O-Ring based upon dimensions measured from a sample. O-rings 48 products containing 18660 Items Product categories.

Select a standard O-Ring and groove based upon a driving diameter. Surface Finish X groove top and bottom. The system pressure itself creates a positive sealing force.

For axial seals with inner or outer pressure piston seals and rod seal applications. Groove dimensions are shown in the tables beginning on page 138. Din ISO Gaskets.

If the Quad-RingX-Ring swells in the application the groove width can be enlarged up to 15 max. O-ring dimensions for the use in a specific groove groove dimensions for the use of a. You can find the largest assortment O-rings at ERIKS.

O-ring in place during installation or maintenance. The ERIKS O-Ring design calculator features the calculation of. Find Your Exact Part Or Use Our Part Interchange Online.

Eriks o ring groove design An complete favorite of mine this all black nail art can make usage of matte and glossAnything with all black is a complete winner for me. Wwweriksinfo Technical Handbook O-rings Quad-RingsX-Rings Gland Design StaticDynamic METRIC The following table shows the groove dimensions for Quad-Rings X-Rings. Theres a thing about black that exudes power and self-assurance.

Evaluation of both any combination of O-Ring and groove. Figure 3 Boss Seals The O-ring is used for sealing straight thread tube fittings in a boss. - With Quad-rings the standard grooves are deeper in comparison with O-ring glands.

Home Products Seals O-rings and accessories. Analyse an existing groove design. O-Ring dimensions for the use in a specific groove.

The O-ring has become the worlds most popular and versatile seal due to its simple shape low. Choose from more than 500000 articles and order right away. The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing role.

These are intended for use in basic design consideration and to understand the core principles involved in o-ring glandgroove design. O-Ring inner diameter stretch outer diameter squeeze. Save time calculating and designing O-ring grooves and verify the O-ring sealing performance by checking parameters like o-ring compression free groove volume o-ring inner diameter stretch and even much more.

The application determines the rubber compound the primary factor being the. Following are some advantages of Quad-rings. The O-ring groove calculator enables engineers to specify an O-ring groove for any given O-ring or vice versa calculates the best suitable size O-ring for any given groove.

This is beneficial for special applications where the O-ring has to be fixed by the groove eg. And load them also into your created design.

Engineering Basics Guide To O Rings Eriks Shop Nl

O Ring Groove Design Seal Design Inc

Engineering Basics Guide To O Rings Eriks Shop Nl

Engineering Basics Guide To O Rings Eriks Shop Nl

0 comments

Post a Comment